Hi, I'm Liz! I've always loved the arts (painting, acting, singing, gluing popsicle sticks together to create a giant castle, soapmaking, etc.), but never planned on making a career of it.

I had been working a full time office job and going to school part time for a couple of years, and only had a few classes left, but I couldn't get them to line up with my schedule. So at the end of 2019, I quit my job to go back to school full time. I finally graduated with a Mathematics degree and a Fine Arts minor in May of 2020, but at that point looking for work had gotten a little weird. The pandemic and quarantine had just hit, and it felt somehow irresponsible of me to go out and look for work and also irresponsible of me to not work. Luckily I was in a position where I didn't have to get a full time job right away, so instead I started driving for Uber Eats delivering food to people, and kept busy taking up the new hobby of making resin dice.

The resin dice idea actually came from back before the quarantine when one of the guys in my D&D group talked about making some. I had worked with resin a little bit in the past, making jewelry for some local bazaars (although my focus was making soap at the time), so when it got brought up my first response was "oh, hey, I could do that." So I bought some cheap molds online and started trying it out. And it was fun! I debated with myself for a long time on whether I wanted to invest in getting my own custom dice designs made since I didn't plan to sell any dice, but eventually I decided to just go for it. I got my custom dice designs and silicone, made some molds, made some dice for friends and D&D buddies, made some galaxy and faux amethyst dice, and put the galaxy and faux amethyst dice for sale on my seldom used Etsy.

I never actually expected to sell any.

I sold all five sets of galaxy dice in two weeks.

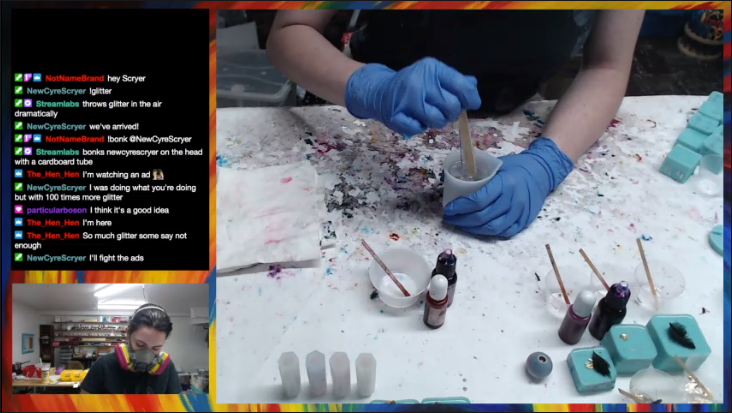

From there, things have grown. I've met a bunch of super nice dice makers, I've started streaming dice making on Twitch, and I've slowly started to build my equipment, dice stock, and sales, and eventually made my own website. It's been amazing. I had dreamed for a long time of having a career in the arts, but always figured I wouldn't be able to support myself doing it. I'm not quite there yet, but I am so excited to follow this path and hopefully be able to make a career out of something I truly love doing.

When I was first looking into making handmade dice and did some looking around to see what was already out there, one of the first things I thought to myself was "Gosh! Why are handmade dice so expensive!?" Well, now I know. Making dice takes a lot of time and precision, requires a lot of specialized equipment, and are pieces of art in their own right.

For a little bit of background, let me walk you through the steps it takes to make a set of dice.

The first step is the setup and pouring of the dice. If you've ever watched one of my livestreams, this is the step you've probably seen. Getting all the materials together and placed where they need to go, then mixing and pouring the resin takes a bit of time! At minimum, pouring three sets takes about two hours to do, although I've done livestreams up to five hours in length! (For convenience, lets go with the two hours and say each set takes 40min minimum to pour)

Next we put the dice in a pressure pot to cure for 24 hours or so under about 40psi of pressure. This takes all of the air bubbles in the resin and squishes them down until they're so small they can't even be seen. This results in crystal clear resin that is bubble free!

After the 24 hours of curing are up, the molds can be removed from the pressure pot, and the dice from the molds. This is the fun part when I finally get to see how the dice turned out! It takes me about 5min to do.

The dice then sit for another 24 hours to finish curing completely.

After the dice have fully cured we move on to sanding. First I use a flat-lap sanding wheel to get the lips and edges and bumps off of the dice, then I move on to hand sanding/polishing. I have a set of polishing papers of various grits and I usually use three different papers to get the dice to a rough finish on the sides that needed sanded. The whole sanding process takes me roughly 40min per set of dice.

These roughly polished dice then get put into a vibratory tumbler with some plastic polish and hardwood media and are left to polish for about a week and a half. I check the dice every morning and evening to see how they are doing and add more polish to the tumbler. Overall, I would estimate that all of the checking and refreshing takes me about 30min per set of dice.

Once they are all polished, the dice get pulled out of the tumbler and put into a bowl of warm soapy water where I scrub them with a soft toothbrush. The numbers of the dice get filled with a lot of gunk from the sanding (resin dust) and polishing (excess polish) and it needs cleaned out. This takes me about 20min per set.

This, leads on to the last step of finishing the dice which is inking (filing in the numbers). I ink my dice with acrylic paint using a small paintbrush and then wipe excess paint off the surface of each face with a paper towel. It's always amazing to me how much the number color can affect the feel of a set of dice; it's like magic! Inking a set of dice takes me about 40min as well.

So overall, between 40min pouring, 5min unmolding, 40min sanding, 30min refreshing the polishing tumblers, 20min cleaning, and 40min inking, that brings us to about 3 hours of work time per set of dice (minimum). And that doesn't even take into account making the molds (they take a couple hours to make), making inclusions to be put in the dice, cleaning up the workspace (which I should do more often), or packaging things to be shipped. Oh boy!